A spin-off from OBO’s new knowledge could also lead to riot police around the world wearing protective gear made in New Zealand.

A $217,000 investment from TechNZ, the business investment arm of the Foundation for Research, Science and Technology, is helping OBO understand exactly what happens to the body, particularly the face and head, when hard balls hit at high speed.

By understanding the science of high-speed, hard ball impacts, body tolerance, injury protection and materials, the company is now better able to create unique products.

“This is a bold step forward for OBO, which is building new knowledge and critical science capability, that will put it on a path to becoming a high growth company,” says TechNZ senior business manager Elisabeth Feary.

OBO already has a world-class reputation for producing field hockey goalie protective equipment, with about 65 per cent of the world’s goalies wearing OBO gear, which is sold into 61 countries.

The TechNZ funding has been used to build a laboratory and develop software to specifically measure ball speed impact and to investigate new materials.

In the lab, a ‘cannon’ fires balls at 200 kilometres an hour, with the motion and impact data providing information that has never been captured in this form anywhere else in the world.

The unique knowledge feeds into the design process, with the lab also used to test the validity of the resulting products. There are international safety standards governing the manufacture of helmets but no such standards exist for face protection so OBO is taking it upon itself to also develop these along the way.

OBO founder Simon Barnett says it was a frustrating exercise to search the world unsuccessfully for scientific information about ball-speed damage, but it also opened up opportunities for his company to identify a new niche market in designing and marketing face protection for a range of sports.

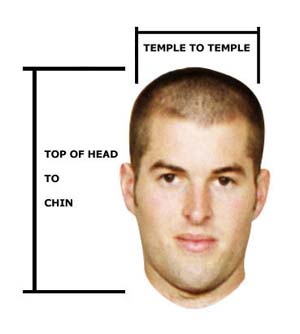

Face protection that allows excellent vision without compromising movement is vital for softball pitchers, wicket keepers and hockey players, who face unpredictable balls when running out to defend during penalty corners. Mr Barnett says faster ball speeds are creating demand for different types of player protection.

“Higher ball speed results in reduced reaction times, greater damage, higher medical and dentistry bills so the need for face protection is now greater than ever before,” he says.

“Having your face reliably protected in these situations means that the player can feel more confident, and play their game to a higher level.”

OBO is aware that it is not only the design and new materials to withstand the impact that are paramount for market success, the beauty factor is important.

“We’ve talked to players and identified their needs and then worked in the laboratory to develop materials and shapes with the necessary performance characteristics and then added the beauty factor.

“The gear has to be functional and the players have to like wearing it, so it has to look good but it also needs to look intimidating to the opposition,” says Mr Barnett.

The results of OBO’s scientific testing are likely to be on the market in about six months, giving the company a whole new product category.

The new face protection will have greater strength than existing face masks but will also take into account that gear needs to give players excellent visibility.

Understanding new materials and designing equipment that takes the impact of potentially bone-breaking activity is also likely to give OBO a foot into new markets, such as protection for police working in riot or dangerous situations where vision and mobility are essential.

“OBO’s new scientific knowledge will underpin future products and is also helping the company in its transition from a niche manufacturer to a global sports company with the ability to break into larger, more profitable markets,” says Dr Feary.

The new products have the potential to increase OBO’s turnover by as much as 600 per cent in five years.

Mr Barnett has never played a game of hockey in his life but he now gets plenty of feedback from his 13 year old daughter who plays in goal for her Palmerston North Girls’ High School hockey team.

Via www.voxy.co.nz